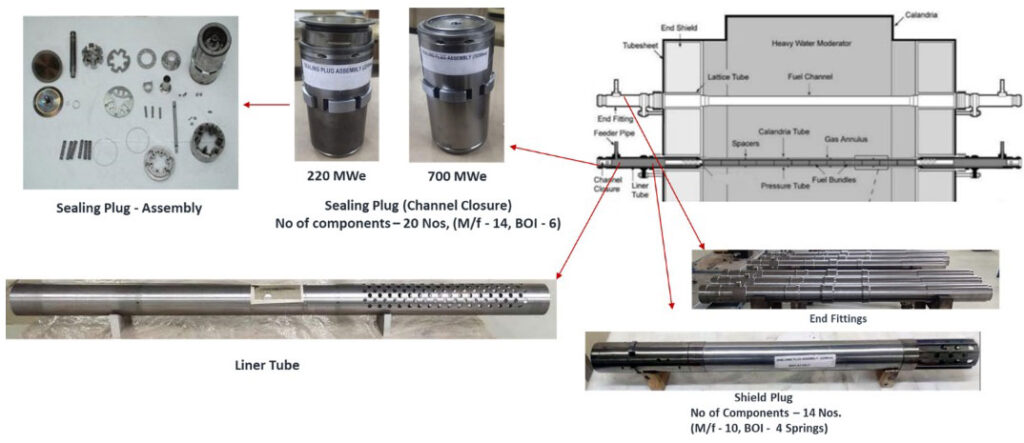

MTAR produces essential coolant channel assemblies consisting of Sealing Plugs, Shielding Plugs, Liner Tubes, and End Fittings, which form the core of civilian nuclear reactors and require the assembly of numerous components.

MTAR produces essential coolant channel assemblies consisting of Sealing Plugs, Shielding Plugs, Liner Tubes, and End Fittings, which form the core of civilian nuclear reactors and require the assembly of numerous components.

Trusted partner in India’s Civilian Nuclear Advancement

MTAR Technologies has been a key contributor to India’s civilian nuclear power program. We have cultivated strong partnerships with esteemed Indian organizations such as Nuclear Power Corporation of India Limited (NPCIL), and continue to deliver precision-engineered products to the core of nuclear reactors.

Our comprehensive product portfolio in the nuclear segment includes complex assemblies such as Fuel Machining Heads, Drive Mechanisms, Bridge and Column Assemblies, and Coolant Channel Assemblies, among others. These critical components are supplied not only for the construction of new Pressurized Heavy-Water Reactors (PHWR) but also for the refurbishment and maintenance of existing reactors.

Through years of expertise in manufacturing products that demand high positional and dimensional accuracy, MTAR has set industry-leading benchmarks in quality and innovation. Our commitment to excellence ensures that we meet the stringent requirements of civilian nuclear reactor operations, positioning us as a trusted partner in India’s civilian nuclear advancement.

A major supplier for DAE for 45+ Years.

Trusted partner for NPCIL

Indigenous manufacturer of Water Lubricated Bearings (WLBs) for nuclear reactors.

Contributed significantly to the various Indian Civilian Nuclear reactors

Strong capability to produce high precision equipment deployed in the nuclear vault

Critical components for Civilian nuclear reactor

Grid plate assembly

Control plug assembly

Inclined fuel transfer mechanism

Key Components and Systems

Fuel Machining Head

Bridge and Column

Coolant Channel Assemblies

Channel Health Assessment System

We have supplied Fuel Machining Head for 220 MW and 700 MW Civilian Nuclear Reactor.

Application: Used for loading and unloading of fuel bundles in the core of the nuclear reactor.

Criticality: Involves manufacture and assembly of over 600 components.

We have supplied Bridge & Column of Bridge Width – 12 m and Column Height – 15 m to the core of the civilian nuclear reactor.

Application: Moves fuel machining head in sideways and vertical directions to allow loading and unloading of the various nuclear fuel bundles in the nuclear reactor.

Criticality: Perpendicularity to be 1 mm in the two column structures.

MTAR is working with BARC to develop Channel Health Assessment System (CHAS). Detailed Design/Engineering, manufacturing and assembly is in process at MTAR. CHAS is one of the few products where the detailed design is also developed by MTAR apart from manufacturing and assembly.

MTAR is working with BARC to develop Channel Health Assessment System (CHAS). Detailed Design/Engineering, manufacturing and assembly is in process at MTAR. CHAS is one of the few products where the detailed design is also developed by MTAR apart from manufacturing and assembly.

Few Features of CHAS :

- Fully Automated

- No human intervention required in FM Vault