Quality

Stringent Quality Control Mechanism

We have an extensive and stringent testing and quality control mechanism undertaken at each stage of the production process to ensure that our finished product conforms to the exact requirement of our customers and successfully passes all validations and quality checks. Towards this end, we use high precision quality inspection equipment such as 3D co-ordinate measuring machines (“CMM”), laser measuring, optical alignment instruments, non-contact measuring, and other such non-destructive testing equipment to ensure ideal quality, as requested by our customers. We also have experienced quality personnel who undertake procedures and inspections such as radiography, ultrasonic, magnetic particle and dye penetrant at our non-destructive testing (“NDT”) facilities.

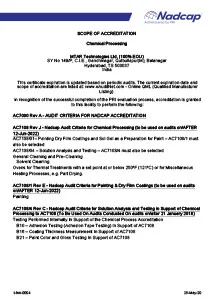

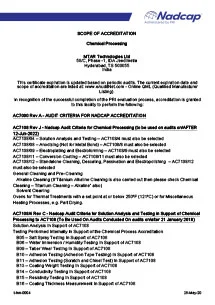

Our capability in measuring and maintaining quality and measurement records at each level of the process is a key enabler. In addition, our facilities are equipped with requisite equipment for dimensional and geometrical inspection to establish micron level adherence to specifications as set by our customers. Most of our manufacturing facilities, including our EOU have accreditations such as the ISO 9001:2015 certification and AS9100D certification (technically equivalent to the EN 9100:2018 and JISQ 9100:2016 certifications) for quality management systems. Our facilities at Unit 2 and EOU are certified for 14001:2015 Environmental Management System, ISO 27001:2013 Information Security Management System, and ISO 45001:2018 Occupational Health & Safety, which is a major milestone in our journey towards being a 100% ESG compliant firm. In addition, we have completed the audit formalities of NADCAP for EOU and MTS.

Inspection & metrology equipment

- 3-D CNC Co-ordinate Measuring Machine (Make : ZEISS 550 X 450 X 400)

- 3-D CNC Co-ordinate Measuring Machine (Make : ZEISS 1600 X 1000 X 600)

- Laser Measuring System (Make : HEWLETT-PACKARD-5528A)

- Universal Measuring Machine (Make : SIP MUL-214B)

- Universal Measuring Machine, MUL-1000

- Surface finish & Roughness testing equip. (Make: PERTHEN)

- Roundness testing machine, (Make: PAV Swiss)

- Leveling Instrument “WYLER”

- TALYROND 265 (RSU) Roundness Measuring System

- FORMTALYSURF-2 (S4C) Contour & Surface finish Measuring Equipment

- NIKON MODEL : V-20B Profile Projector

- All conventional measuring & inspection instruments of different sizes/types/makes (including Digital/Electronics items)

Quality control facilities

- We have a well established QA Group meeting to global standards.

- Full fledged facilities for all QC and QA activities(3D CMM’s , Laser Measuring Instrument etc.)

- Experienced personnel for Procedures and Inspection Plans .

- Traceability / Identification records for all stages

- Full fledged NDT facilities as follows

- Radiography

- Ultrasonic

- Magnetic Particle

- Dye penetrant etc.,

- Quality Persons at different levels available.

- Fully equipped with requisite facilities for Dimensional & Geometrical Inspection

Certifications

WHAT OUR CLIENTS SAY ABOUT US

Dear Mr. Reddy,

The successful launch of the GSLV MK3 on 5th June 2017 enables the country to assume a strong and independent position in space transportation using efficient launch vehicle technology. Our collaboration with you has unfolded very effectively, thanks to the experience and industry expertise of MTAR staff and the sustained support of MTAR management also merits special gratitude. The results speak for themselves and are proof of great team performance. Congratulations Team MTAR, Milestone Accomplished!

With warm Regards,

Thank you very much for your complementary message and inspiring words on the successful launch of GSLV Mk-III/M1 Chandrayaan-2 Mission. On this occasion we hereby acknowledge the excellent contribution of your team also in the successful mission. We expect the continued co-operation and support from your side in future missions also.

Dear Shri PJ Reddy,Thank you so much for your warm greetings. Convey my greetings to the Executive Director, Shri Satyanarayana Reddy and Shri Srinivas Reddy and to the entire family. While in LPSC, I was very strongly associated with you. I am sure that you in MTAR will be reinforcing a strong bond with LPSC and will be contributing significantly. I cherish the association and expect more tasks to be accomplished banking on your expertise in aerospace manufacturing area.

Contact Us

MTAR Technologies Limited, 18, Technocrats Industrial Estate, Balanagar, Hyderabad, Telangana 500037

Phone number: 040 4455 3333

Email: info@mtar.in