MTAR has Eight Big Sized Manufacturing Units

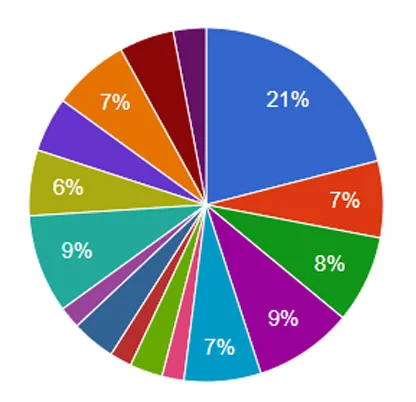

with the following Types of Machines

- CNC Turing Machines

- Jig Boring Machines

- Machining Centres

- Milling Machines

- Turing Machines

- CNC Turn-Mill Machines

- Deep Hole Boring Machines

- Deep Hole Drilling Machines

- Horizontal Boring Machines

- Vertical Turning Machines

- EDM Machines

- Furnaces and Surface Treatment Equipments

- Thread Grinding Machines

- Cylindrical Grinding Machines

- Surface Grinding Mahines

- Honing Machines

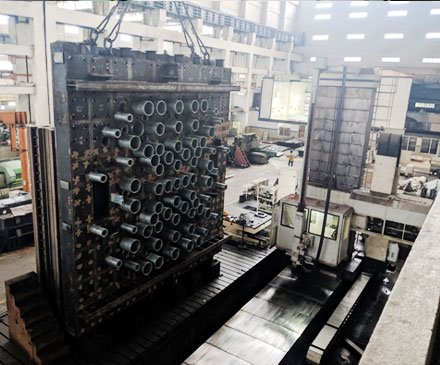

Deep Hole Boring machines for carrying maximum material removal.

Capability: Can accommodate

Bore Dia 600 mm * 6000mm

Capability: Can accommodate

Bore Dia 40 mm * 3000mm

Bore Dia 3 mm * 20 mm

Capability: Can accommodate a Job up-to Dia 800 mm * 6000mm

Capability:

X – 14000 mm Y – 5000mm Z – 2400 mm

WHAT OUR CLIENTS SAY ABOUT US

Dear Mr. Reddy,

The successful launch of the GSLV MK3 on 5th June 2017 enables the country to assume a strong and independent position in space transportation using efficient launch vehicle technology. Our collaboration with you has unfolded very effectively, thanks to the experience and industry expertise of MTAR staff and the sustained support of MTAR management also merits special gratitude. The results speak for themselves and are proof of great team performance. Congratulations Team MTAR, Milestone Accomplished!

With warm Regards,

Thank you very much for your complementary message and inspiring words on the successful launch of GSLV Mk-III/M1 Chandrayaan-2 Mission. On this occasion we hereby acknowledge the excellent contribution of your team also in the successful mission. We expect the continued co-operation and support from your side in future missions also.

Dear Shri PJ Reddy,Thank you so much for your warm greetings. Convey my greetings to the Executive Director, Shri Satyanarayana Reddy and Shri Srinivas Reddy and to the entire family. While in LPSC, I was very strongly associated with you. I am sure that you in MTAR will be reinforcing a strong bond with LPSC and will be contributing significantly. I cherish the association and expect more tasks to be accomplished banking on your expertise in aerospace manufacturing area.

Contact Us

MTAR Technologies Limited, 18, Technocrats Industrial Estate, Balanagar, Hyderabad, Telangana 500037

Phone number: 040 4455 3333

Email: info@mtar.in